MIRS Robotic Sampler implemented at Impala Terminals, the world’s largest roofed mining export terminal located in Callao, Lima-Peru, which markets ore concentrate with a capacity to handle 2.8 MMT per year. The client required to optimize the sampling work and make it more efficient and safer considering the number of trucks to be sampled per day.

The concentrate sampling process is crucial for transactions between producers and their customers. This process determines the humidity and the amount of fine ore present in que concentrate, variables that, in the event of sample manipulation and systematic procedural errors, can mean differences of thousands of dollars. Given this, the client was looking to implement a more robust and reliable sampling system that would allow them to reduce the associated errors and increase the reliability of the process.

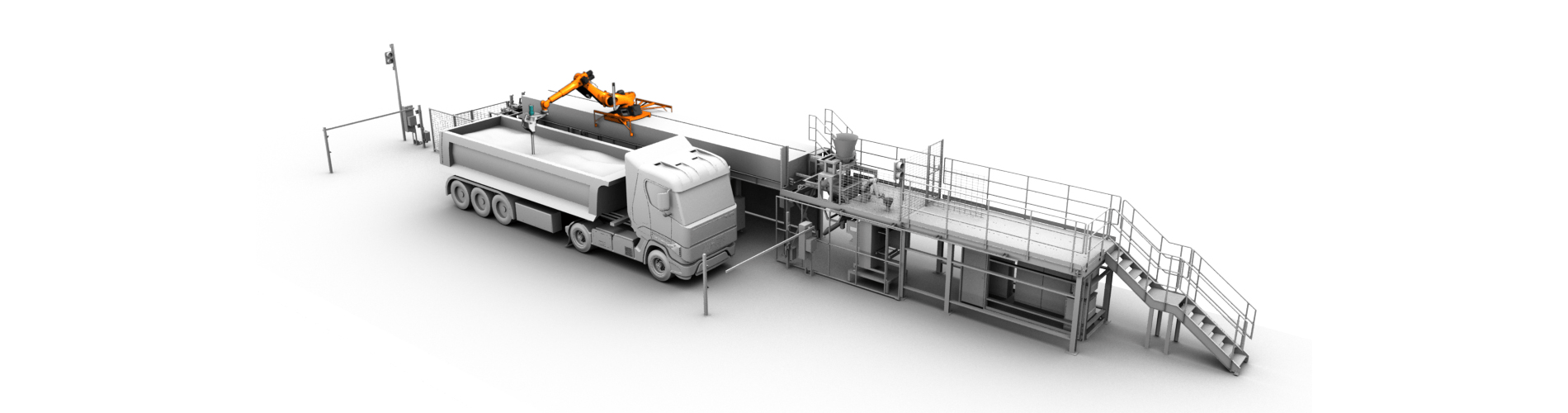

To address this problem, the MI Robotic Sampler solution was implemented, a fully robotic system that was designed, developed, and implemented with state-of-the-art German robotic technology, high quality, and precision for sampling mineral concentrates (copper, molybdenum, cobalt, zinc, lead, among others). 2 Sampling robots were employed, giving the ability to sample 3 lanes of truck carrying ore concentrate. Each robot is mounted in a rail, allowing for a complete reach of the trucks surface. The robots can also interchange sampling tools automatically, which allows for multiple ores to be sampled by the same robot, without cross contamination risks.

The solution allowed representative and unbiased samples to be obtained, providing full depth of penetration for the sampling column. Being fully robotic and having minimal human interaction significantly reduced process error. In addition, it minimized sampling times because it was programmed as needed, giving the ability to output more trucks a day.

This implementation removed personnel from exposure to harmful minerals and contaminants, raised sampling quality standards, reduced operating costs, and increased productivity, thanks to its proven and reliable technology.