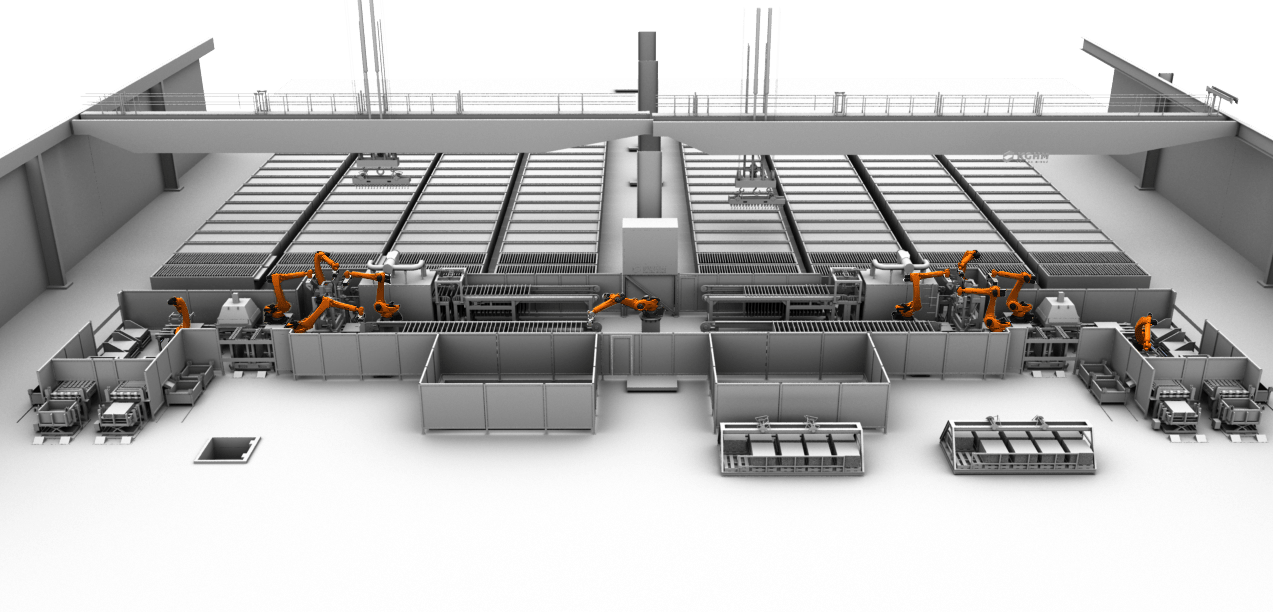

MIRS Robotic Starter Sheet Stripping Machine implemented in ASARCO Amarillo Refinery, located in Amarillo, Texas – USA. The innovative system allows starter-sheets to be detached from titanium plates, without human intervention and the risks associated with so, significantly improving the occupational health and safety of the workers, who previously performed this task.

The Starter Sheet Stripper is an autonomous unit, designed and developed by MIRS to automate this process, also improving the quality of the final product and safety standards. In traditional cathode refining, the manual peeling of starter sheets is a heavy and risky task for workers health, so the incorporation of robotic technology helps to avoid repetitive and accident-prone work, as well as affecting relevant factors such as cycle time and operational performance.

The robotic Starter Sheet Stripper incorporates reliable, safe and efficient technology, with high safety standards and millimetric precision, an intrinsic benefit when implementing robotic technology. This application adapts to the high demands of the existing processes in the mining industry, such as mobile and fixed take-off stations, reaching performances that only this type of available technology can provide.

MIRS Robotic application at ASARCO’s site decreased the cycle time of the starter sheet take-off, being a faster, safer and more reliable. It also improved the occupational health and safety of the workers, that previously performed this task, which was repetitive and extended to plus 12 hours, leading to injuries, ailments and constant exhaustion. Quality wise, the classification of the sheets improved considerably given that the vision systems implemented in the solution and a weighing station that determines the classification of the sheets with little to no error.