Integral maintenance, a new concept that goes hand in hand with the incorporation of robotic technology into the process

14 December 2016Maintenance is a key factor for modern mining production. Positively influencing this concept is a necessary condition to advance in relevant areas such as the safety of people and programmed production, thus constituting the concept of integral maintenance.

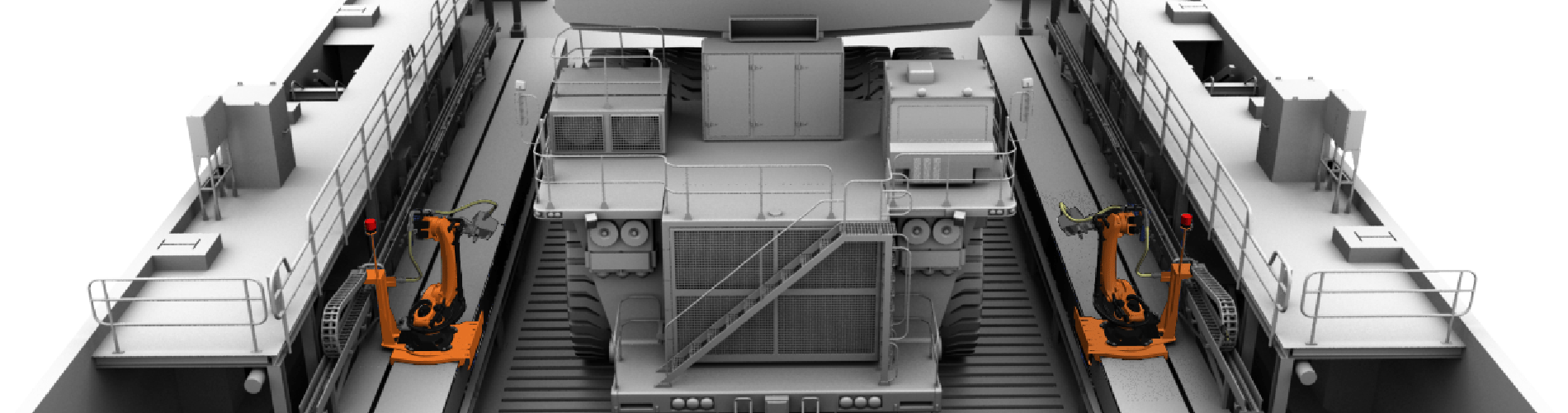

Mirs, a company recognized for designing, integrating and manufacturing robotic products and solutions, capable of performing in highly variable industrial processes, allowing its customers to incorporate productivity, safety and quality to their processes, has promoted a set of robotic applications implemented for mill maintenance, reducing human interaction to the maximum and decreasing the time normally considered in the maintenance that accompanies the milling process.

These solutions are made up of high quality and world class robots, making it a more precise, safe and profitable operation system.

With the idea of reinforcing the concept of integral maintenance, MIRS has proposed to the market a series of applications that act together and thus allow the integrity of the maintenance process, since all the dynamics are covered through this system that interacts with each other.

These are the Robot for removal and retorquing of nuts and bolts in SAG mills, the Robotic Manipulator of mill liners, the Robotic Manipulator of trommel blades, and the Ball Loading. For the operators and maintainers of concentrator plants, the mere thought of being able to intervene the mill at any time, without mobilizing external personnel, and to be able to carry out a total or partial change of liners in half or a third of the time, is a reality today.

MIRS has already taken important steps in this direction. It is the launching to the national market of the new MI robotic SAG Mill product line, and specifically, of the Trommel Robotic Pallet Handler.

This launching will take place tomorrow, December 15, and will gather a wide range of operators who will have the unique opportunity to witness live and direct a physical test of one of the largest robots in Latin America, demonstrating its millimetric precision and strength capacity. In the future, MIRS as a leading company in the development of robotic solutions, is preparing activities where the market will be able to know the other components of MI ROBOTIC MOLINO SAG and its concept of integral maintenance.