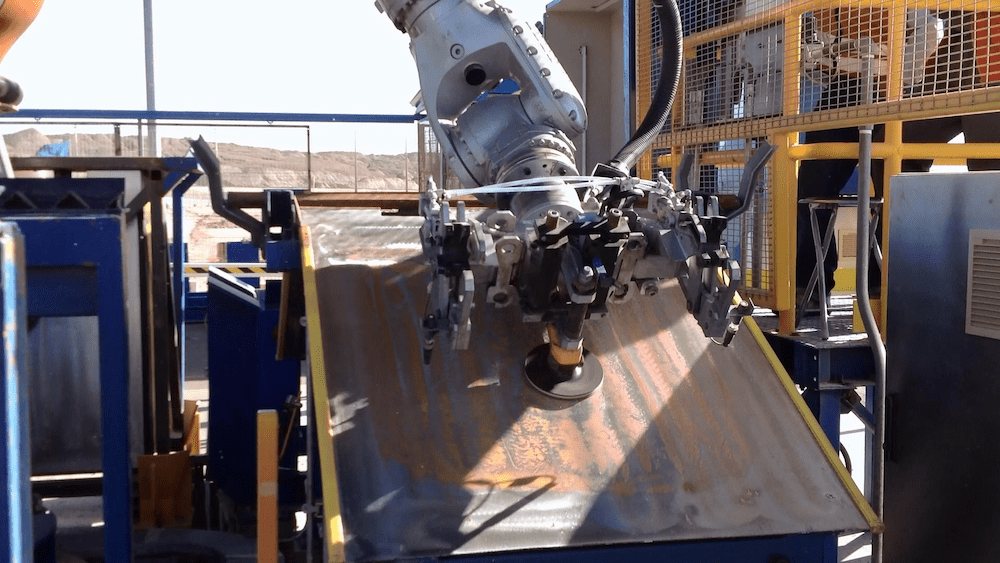

It is a self-contained unit, designed and developed by MIRS to polish base plates that have already been used in their take-off stage and that need to be reused in the next cathode harvesting process. It is a robotic solution that is easy to install, with a compact design, that does not require civil works and that requires a minimum of operator intervention in the process. Its polishing program, build from the best experiences, will polish any type of base plate, and minimize its impact, leaving it ready and available for the next harvest. Its compact design allows it to be installed near the warehouse or in the maintenance yard, reducing plate handling costs. It also considers a sub-operation of “zone polishing”, which allows the operator to designate specific sectors where the machine can polish.

Benefits

- High precision polishing

- Lengthens base plate life

- Improves adherence capacity of the cathode

- Decreases risks of accidents and replaces human labor from extenuating tasks

- Eradicates bad operational practices

- Increases base plate availability and control

Enquiry

Base Plate Polishing