MIRS projects high demand for its robotic solution for mill liner changes

1 April 2021The application, developed in Chile and unique in the market, reduces maintenance hours by 40 to 50 hours, eliminates operator exposure to risks, improves equipment control, and provides greater reliability to mining concentrators.

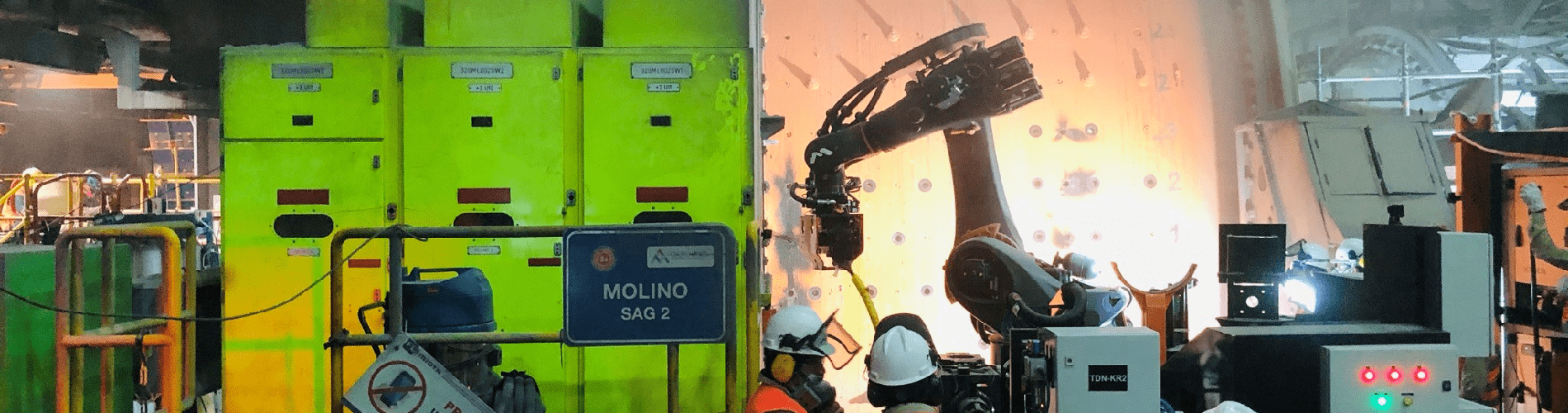

A faster, safer and better quality process is offered by the robotic mill liner change solution developed by Mining Industry Robotic Solutions, MIRS, a subsidiary of HighService Corp.

Under the slogan “Nobody in the mill” and after extensive analysis and multiple tests, the national company was able to implement this application that allows the complete transformation of a hitherto manual task into a fully automated one, which is carried out in less time.

“It is a unique solution. There is no alternative on the market that compares to it, since what is available does not eliminate the presence of people in the mill, nor can it be faster,” says Igor Elías, MIRS Milling Business Line Manager.

ADVANTAGES

One of the main advantages of robotic casing changeover is that customers are no longer faced with the dilemma of choosing between safety and speed of operation.

“In terms of safety, we reduced people’s exposure by 100%. We are not talking about developing an administrative procedure or work permit, putting up a barrier or fence, or using a harness, which are preventive measures, but rather eliminating the risk,” he says. In addition, this solution makes it possible to perform tasks up to 35% faster than the current process of

coating changes. “One hour of maintenance represents about US$150k to US$250k of production,” he says.

“It is a unique solution. There is no other alternative on the market that compares to it, as it

that what is available does not eliminate the presence of people in the mill, nor can it be faster,” Igor Elías.

PROCESS QUALITY

Elias points out that another benefit is the quality of the process. “Today, the installation of coatings is done in a hurry and is left to the judgment of the operator. With robots, however, it is possible to establish a level of quality that has never been achieved before. And that allows better operational control of the mill. There will be fewer incidents, which leads to improved reliability,” he says. “The robot controls all installations. It cleans, lubricates, installs, does the calibrated torque, delivers a digital certificate of the bolt and moves on to the next one. And all of that can be verified online,” he explains.

To realize this solution, MIRS created in 2019 a division specially focused on liner change, with close to ten industrial tests performed at customer sites to date. In addition, in its facilities it built two full-scale SAG mills of 36 and 38 feet, and one ball mill of 24 feet in diameter, which has allowed completing more than 16 months of continuous tests on full-scale equipment.

SUPPLY AND PROSPECTS

The company’s offer covers both robots that go on the outside and those that operate inside the mills. The former are already commercially available, so any customer can request an evaluation to specify the system they require, and proceed to implementation in a safe manner.

While the inner machine is at a preliminary stage, in the middle of the last stages of development validation to proceed to manufacturing.

In terms of contracts, the company has made progress with two large customers in Chile, and is in talks with three operations located in Peru. And through its offices in the United States and Australia it will begin a strong sales campaign, so its expectations are very high. “And no less relevant is that the robotic coating change is not only made in Chile, by Chileans and with local master craftsmen, but it also has the merit of solving technological problems that until now had not been solved in any country,” concludes Elías.