Robotics: key to achieving Mining 4.0

2 September 2016The country’s main producing company CODELCO, joins this trend that has already become a focus of foreign investment.

According to an article recently published by the CODELCO EDUCA portal, robotics is one of the key technologies to keep Codelco competitive in the international scenario, where today, more than ever, the technological bet is key.

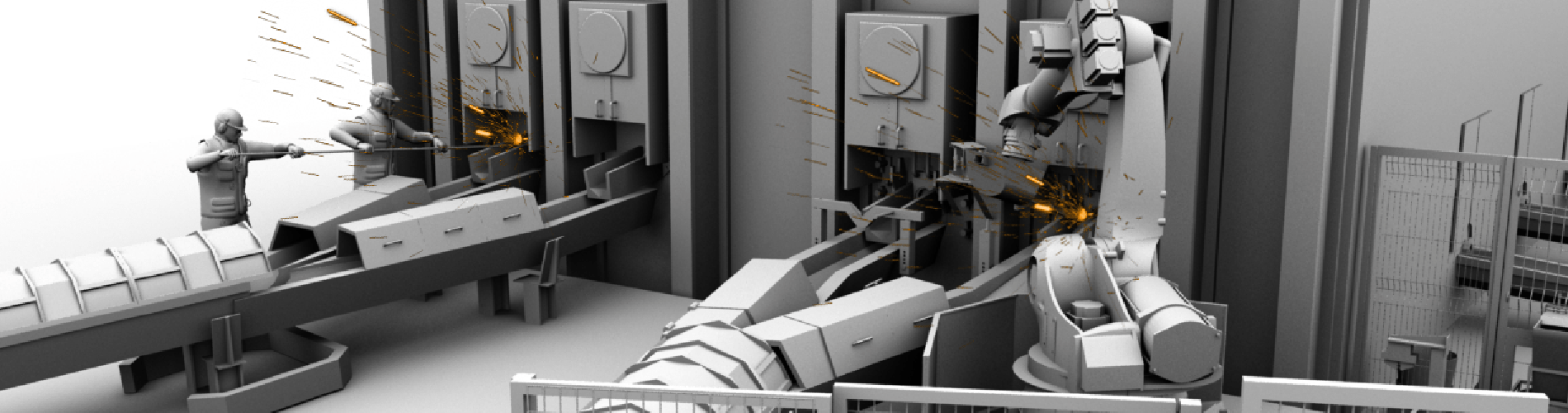

The era of robotics is already present in many industrial niches, such as mining. In Chile, the main copper company has already taken great steps in this direction with the development and implementation of various automated solutions that have brought answers to problems ranging from the need to streamline production processes to the replacement of labor in tasks that represent a possible risk to people. At this point, it is worth highlighting the strategic role that MIRS has developed together with Codelco as its robotic technology supplier.

One of the technological focuses of application is cleaning, a process that is often complicated in foundries due to the nature of the materials to be treated and the dimensions of the spaces.

To facilitate these tasks, Codelco implemented two robotic solutions developed by MIRS.

The first one focuses on molybdenum roasting furnaces. Here, the machine is synchronized with the rotation of the moving furnace, to thoroughly clean the space between the teeth of the furnace. Its use has facilitated the task of the operators, in addition to fixing the periodicity of the cleaning, which in turn allows a better transport of loads inside the furnace.

On the other hand, Codelco implemented the “Robot for opening and closing passages in melting furnaces” system developed by MIRS. Completely autonomous in its operation, it not only cleans the discharge channel of the flash furnace, but also burns and takes samples, automatically replacing its tools at the end of each task. Its operations are controlled by an independent panel, which can also be commanded from a control room.

Some of its tools, which were also developed by MIRS, are: a lance guide for burning; a gripper, which includes a sensing system to define movements and speed; a hydraulic cylinder for plugging; and a hammer for chopping and sampling the slag at high temperatures.

CODELCO, after implementing this robotic technology in Chuquicamata, assimilated the benefits in its operation, especially for the workers, since it protects them from working at high temperatures, also reducing operational costs and helping to establish a continuous flow of slag, thus increasing the useful life of the equipment.

Worker protection

A factor that is always present in the development of processes and action guidelines is the reduction of risks and the occurrence of labor accidents inside the mine and also during the processing of material, being these some of the main evaluations when it comes to implementing state-of-the-art technology.

Another example of this view within the industry and in relation to the applications proposed by MIRS to address the safety of workers, is the case of the use of a robotic gipper for taking and positioning base plates, located in the Radomiro Tomic mine, a solution implemented by MIRS.

The objective is to spare the operators the difficult and dangerous task of moving the huge and heavy plates. The robotic application, equipped with special sensors and an effective communication system, manages to lift and move the cathodes on its own, maintaining the synchrony of the process, due to its ability to coordinate with the existing automatic take-off machines. This technology not only protects workers and reduces operating times, but also avoids empty spaces in the location of base plates and prevents mistreatment of the steel plates. By way of conclusion and rescuing the guidelines that focus modernization in mining, that is, the safety of people and the incorporation of new technologies to the processes, it can be stated that the industry has begun a phase of great development of tools and processes, which together with improving and betting on productivity come to support one of the most important pillars of the moment, the safety of people, an area in which a technological development company such as MIRS has much to contribute.